264L 3000W Ultrasonic Fuel Injector Cleaning Machine

Product Details:

| Place of Origin: | SHENZHEN CHINA |

| Brand Name: | SKYMEN |

| Certification: | CE,ROHS,FCC,PSE |

| Model Number: | JP-600ST |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 pc |

|---|---|

| Price: | negotiable |

| Packaging Details: | 1120*1460*1070mm Wooden case |

| Delivery Time: | 7 working days |

| Payment Terms: | T/T, Western Union, L/C, L/C |

| Supply Ability: | 20.000 pcs per month |

|

Detail Information |

|||

| Tank Size (LxWxH): | 800x600x550mm | Unit Size (LxWxH): | 1060*1400*950mm |

|---|---|---|---|

| Package Size (LxWxH): | 1120*1460*1070mm Wooden Case | Machine Type: | Industrial Ultrasonic Cleaner |

| Capacity: | 264L | Frequency: | 28/40Khz |

| Ultrasonic Power: | 3000W | Heating Power: | 6000W |

| Highlight: | 264L Ultrasonic Fuel Injector Cleaning Machine,3000W Ultrasonic Fuel Injector Cleaning Machine,3000W ultrasonic injection cleaning equipment |

||

Product Description

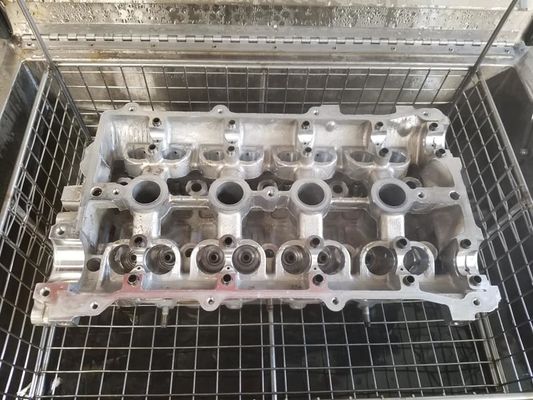

264L Engine Block Industrial Ultrasonic Cleaner ,Ultrasonic Engine Cleaner

In engine rebuilding work, ultrasonic cleaning is prevailing as efficient, fast and adaptable to any stage of the production chain.

Ultrasonic cleaning removes all types of residue in cylinder heads, valves, pistons, motor blocks, commutators, alternators, etc. respecting the most delicate surfaces and ensuring a flawless finish both for the subsequent assembly processes and the final presentation of the engines.

The harsh working conditions to which this type of machinery is subjected to make preventive maintenance a fundamental task to lengthen their useful life and smooth operation.The Motor Clean ultrasonic cleaning equipment facilitate cleaning radiators, cylinder heads, engine blocks, transmissions, hydraulic systems and working tools, such as shovels or chains, thereby contributing towards a correct maintenance that favours the efficient work of heavy machinery and decreases the possibility of unexpected breakdowns.

![]()

The feature for skymen industrial ultrasonic cleaner JP-600ST

1. stainless steel tank has resistance to wear and long work life.

2. tank capacity:264Liter

3.Use just tab water, or industrial alcohol and solvent cleaner for more higher cleaning requirement

5.industrial control chip microcontroller.flexible circuit boards control, more secure & stable

6.with drainage,basket,lid and Multi-direction castors

7. Transducer : Korea techinique

8. PCB board is independent research and development design production by skymen

9. It can applied to clean cast iron, steel, stainless steel, brass, bronze

![]()

| model | JP-600ST |

| ultrasonic frequency | 28KHZ/40KHZ |

| Material | SUS 304 OR 316 |

| tank size | 1060*1400*950mm |

| product size | 820x685x835mm |

| package size | 1120*1460*1070mm Wooden case |

| Transducer | 60pcs |

| Rated power | AC380V, 3 phase/50Hz |

| ultrasonic power | 3000W (40%-100% adjuatable) |

| heating power | 6000W (20°C to 95°C adjustable) |

| timer | 1-99 hours adjustable |

| G.W | 195KG |

| N.W | 161KG |

Things to consider when buying an industrial ultra sonic

Cleaner Size: In ultra sonic cleaning size does matter. Make sure that you are looking at the tank dimensions and not just the outside dimension.

Ultrasonic Power: Make sure there is enough power. Compare the watt to gallon ratio."We only sell equipment that has more than enough power!"

Ultrasonic Frequency: Different frequencies clean differently."SKYMEN sells 28khz/40kHz which are both strong and can be used for a variety of cleaning.

Durability: When looking at cleaners you will want only ones with a stainless steel tank."All of SKYMEN ultrasonic cleaner tanks are 14gauge SUS304/316L"

Design: This is something you have to look at every day and possibly customers will be seeing your equipment too."skymen offers the most modern designs and controls"

Repairs: Being able to repair your machine to get back up and going is important. Not only does skymen make sure that every component has an easy access panel, but we are always available to help.

Features: Things like liquid level shutdown are important not just for safety but also the life of your machine. Also wave sweep is important to cancel dead spots to get a more powerful cleaning and timer to shut off in case you forget about it being on."This is standard on all of our machines"