Waterproof SUS316 Phased Array Ultrasonic Transducer 1200W

Product Details:

| Place of Origin: | China Guang dong |

| Brand Name: | SKYMEN |

| Certification: | CE ROHS FCC |

| Model Number: | JP-1024I |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | US$900~1200/set |

| Packaging Details: | Plywood box |

| Delivery Time: | 15 working days |

| Payment Terms: | T/T |

| Supply Ability: | 6000 set/month |

|

Detail Information |

|||

| Material: | SUS316(or SUS304) | Power: | 1200W |

|---|---|---|---|

| Transducer Quantity: | 24 | Cable Lead Out: | Rigid/hose Tube |

| Mounting Type: | Wall/bottom Mounted | Sample: | Available |

| Frequency: | 28KHZ, 40KHz | Use: | Degreasing, Burnishing, Other |

| Feature: | Critical Cleaning / Residue Free, Rust / Corrosion Inhibitor, Non-Toxic, Safe, High Cleaning Speed | Cleaning Process: | Solvent Cleaning, Water Cleaning |

| Highlight: | SUS316 Phased Array Ultrasonic Transducer,1200W Phased Array Ultrasonic Transducer,Waterproof Piezo Ultrasonic Transducer |

||

Product Description

SUS316 Phased Array Ultrasonic Transducer Waterproof Piezo Ultrasonic Transducer 1200W

Common Applications – Advantages of Immersible Ultrasonic Cleaning Transducers

Drop in ultrasonics addition to existing manufacturing cleaning process lines (aqueous cleaning lines, passivation, plating lines, or other part finishing processes which require from microscopic surface scrubbing agitation)

The stainless steel box heavy duty design with completely sealed components allow for precision ultrasonic cleaning in conditions normally too harsh for such precision electronics

Valve bodies and manifolds with small internals not accessible for cleaning by forced spray or mechanical removal

Medical device stainless steel parts cleaning

Aerospace parts cleaning

Ultrasonic part cleaning of water soluble machining coolants, chips, particulate, and true machining/cutting oils, buffing, polishing and lapping compounds which require mechanical surface scrubbing to remove.

General washing for maintenance, manufacturing, rework and/or remanufacturing.

Specification:

Model: JP-1024i

pack size: L430*W280*H100mm

Ultrasonic power: 1200W

Ultrasonic frequency: 40KHZ

Lead-out way: Rigid tube/hose tube

Material: SUS304

110V/220V 60hz/50Hz,

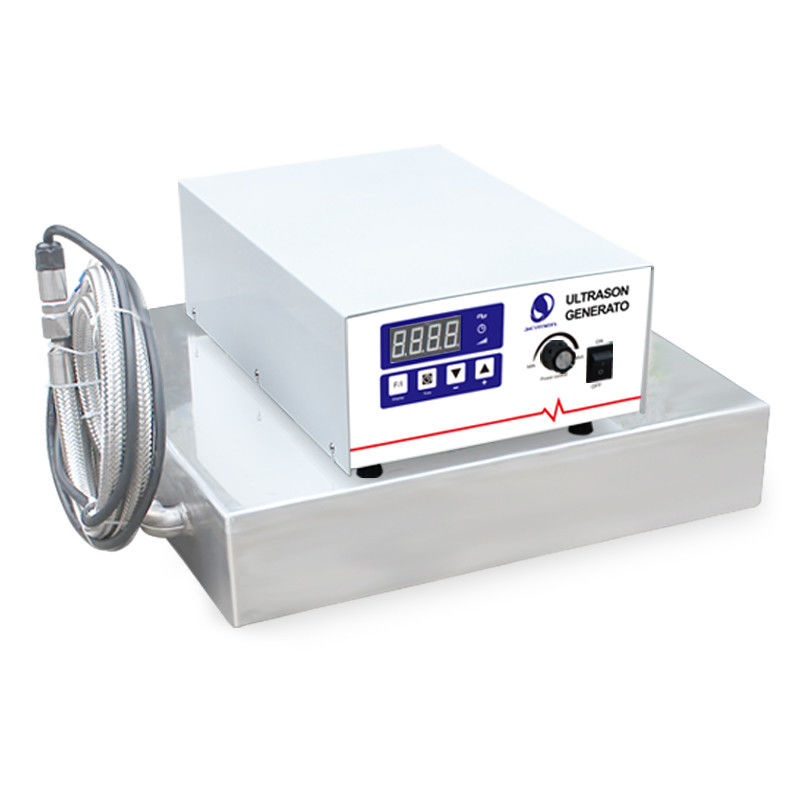

Come with generator

![]()

Immersible ultrasonic transducers are sealed stainless steel enclosures which allow for adding ultrasonics to parts cleaning new tanks or adding onto existing tanks, equipment and systems. This addition allow for uniform precision parts cleaning of the part surface by using ultrasonic frequencies to cavitate the aqueous solution molecules in the tank.

Immersible Ultrasonic Cleaner Transducer Power Sizing and In-Tank Placement

The number and placement of the submersible ultrasonic cleaning transducers is primarily determined by the volume of liquid in the tank, geometric layout of the existing tank, and load size of the parts. Depending on the size of the tank and parts cleaning application, the Watts of ultrasonic power per gallon or Watts/gal can vary from 30 to 100+ W/gal.

The immersible ultrasonic transducers can be mounted on the sides or bottoms of the parts washing/cleaning tanks, depending upon their geometry. In general, side mounting is recommended for tanks where the depth is more than two times the smallest of the length / width and side mounting the ultrasonics reduces the debris and foreign material from settling on the top of the transducer box which will reduce the ultrasonic effectiveness.

Bottom Mounted Immersible Ultrasonic Transducer Box and Generator

These submersible ultrasonics can be made in 28 kHz frequency, for tough to clean parts like engine blocks and mold cleaning burnt on carbon, and 40 kHz frequency for general parts cleaning including precision machined components, in an agitated immersion parts washer or stationary metal sided tanks. Immersibles are not typically added to polypropylene, PVC, PVDF or other plastic based tanks as the plastic absorbs the ultrasonic energy thereby reducing the cavitation energy delivered to the part surface.

![]()

Side or wall mounted Immersible Ultrasonic Transducer Box and Generator

![]()

SUS304 28khz/40kHz Immersion Ultrasonic Cleaner Skymen Waterproof Ultrasonic Immersible Transducer

Why need the Immersion Ultrasonic Cleaner?

If you have your own water tank, to get transducer packs would be good to make the cleaning effect more efficiency!

Features of Ultrasonic Immersible Transducer

Entire stainless steel structure: acid proof and bears the alkali,artistically and durable.

Adopt fission style structure: high frequency connection with jack on is used between ultrasonic immersible transducer and the ultrasonic generator, useful and maintains conveniently.

![]()

| Model (JTM models) | JTM-1006 | JTM-1012 | JTM-1018 | JTM-1024 | JTM-1030 | JTM-1048 | |

|

Ultrasonic transducer box size (mm) |

L | 305 | 355 | 406 | 500 | 550 | 600 |

| W | 250 | 305 | 305 | 355 | 406 | 460 | |

| H | 100 | 100 | 100 | 100 | 100 | 100 | |

|

Housing material |

SUS304/SUS316L | ||||||

|

Surface finishing |

Hard-Cr plating treatment (20+microns) | ||||||

|

Ultrasonic frequency |

28KHz / 40KHz | ||||||

|

Ultrasonic transducers |

6pcs | 12pcs | 18pcs | 24pcs | 30pcs | 48pcs | |

|

Ultrasonic power |

300W | 600W | 900W | 1200W | 1500W | 2400W | |

|

Electronic generator |

KG300 | KG600 | KG900 | KG1200 | KG1500 | KG2100 | |

| Ultrasonic generator work separately control transducers | |||||||

|

power Supply |

AC 110V/220V or 220/240V, 1,13AMP | ||||||

|

Remarks So for the price, please contact our Sales Representative, we will reply you soon. |

|||||||

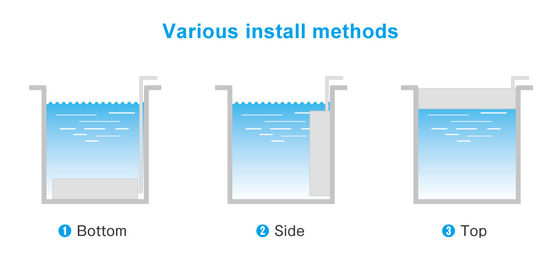

There are many ways to install the ultrasonic immersible transducer: set on the bottom, surface, the side or the topof cleaning tank according to needs.

![]()

![]()

Application of Ultrasonic Immersible Transducer

Pre-plating cleaning for parts to be plated, oil and dirt removing for metal mechanical. Parts, cleaning semi-conductor Si-chips, spectacle frames and glass vessels.

Lens, sunglasses, short-sighted mirror and prism, the microscope, camera, glass equipment, etc.

Plywood packaging show

![]()

![]()

![]()

Advantage of Skymen Waterproof Ultrasonic Immersible Transducer

1. Easily adapted to existing process lines;

2. Industrial Design, and Durability;

3. High efficienty magnetostrictive transducers;

4. 40K Or 28KH for varies cleaning objects.

SUS316 Phased Array Ultrasonic Transducer Waterproof Piezo Ultrasonic Transducer 1200W

Ultrasonic Cleaning FAQs

Q:Can an ultrasonic cleaner properly clean blind holes and top parts of items?

A: If the blind holes and top parts of the items are accessible to the cleaning solution, these areas can be thoroughly cleaned by the ultrasonic cleaner.

Q:How long should the cleaning process be?

A: Usually 8-15 minutes is ok. The length of time needed to clean items depends on factors such as the cleaning solution, contaminants, temperature, and how clean you want the items to be. As soon as the ultrasonic cleaner is put into operation, some of the contaminants are removed right away. Adjusting the cleaning time is usually done to make up for anything that is lacking in the other factors involved in the cleaning process. Unless you are already an expert in ultrasonic cleaning, you should determine the amount of time needed to properly clean a particular item by actually cleaning it.