Skymen SUS316 Roller Style Ultrasonic Cleaning System For Coin

Product Details:

| Place of Origin: | China |

| Brand Name: | SKYMEN |

| Certification: | CE, FCC, ROHS |

| Model Number: | JP-1035S |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | 6000~10000 per set |

| Packaging Details: | Plywood box packaging |

| Delivery Time: | 15~25 working days |

| Payment Terms: | T/T |

| Supply Ability: | 5000 PCS per month |

|

Detail Information |

|||

| Application: | Mold Cleaning | Type: | Multi-tank |

|---|---|---|---|

| Tank Material: | SUS316 | Housing Material: | Stainless Steel |

| Filtration System: | Optional | ||

| Highlight: | roller style ultrasonic cleaning system,Skymen ultrasonic cleaning system,SUS316 ultrasonic cleaning system |

||

Product Description

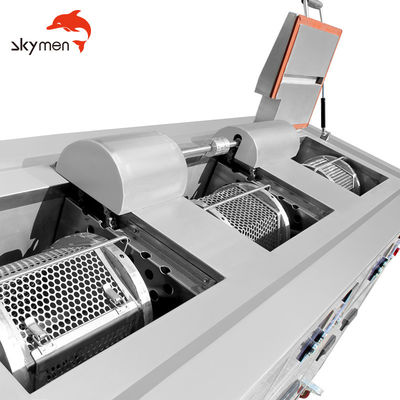

Roller Cleaner Ultrasound Cleaning Equipment

First stage ultrasonic clean: It is mainly used for the powerful cavitation impact effects cased by the ultrasonic wave, aim to clean the dust impurities, grease, abrasive particles, etc. on the surfaceof the parts.

Second stage bubble rinsing: Connecting to the compressed air, to accelerate the parts surface with the stripping of dirt, cleaning agents, etc, thus to ensure the parts surface cleanly and efficient cleaning effects, as well as be available to the next drying procedure.

The third stage hot air drying: Heating device adopts heating package. The heating package adopts stainless

steel air heating tube, with overheating protective fittings. The ring pipeline is made of stainless steel polishing tube with insulation cotton attached. Air duct arrangement: the bottom and the twoleft and right sides of the inner tank, are provided with air supply and air return inlet, forming the air return reflux circulation duct. The hot air is evenly exposed to the surface of the parts, SO for parts evenly heated and quickly drying out.

| Model | JP-3048GH | JP-3072GH | JP-3144GH | JP-3216GH | JP-3288GH |

|

1st tank tank size |

550*400*350 | 600*500*450 | 1000*600*600 | 1000X900X600 | 1200X1000X800 |

|

Rinse stage tank size |

550*400*350 | 600*500*450 | 1000*600*600 | 1000X900X600 | 1200X1000X800 |

| Tank size for drying | 550*400*350 | 600*500*450 | 1000*600*600 | 1000X900X600 | 1200X1000X800 |

| Tank capacity | 77L each | 135L each | 360L each | 540L each | 960L each |

| 1st tank sonic power | 1200W | 1800W | 3600W | 5400W | 7200W |

| Rinse tank sonic power | 1200W | 1800W | 3600W | 5400W | 7200W |

| Dryer power | 750W | 750W | 750W | 1100W | 1500W |

| Clean tank Heating power |

3000W | 4500W | 9000W | 18KW | 27KW |

| Rinse tank Heating power | 3000W | 4500W | 9000W | 18KW | 27KW |

| Dry tank Heating power | 2600W | 3000W | 4500W | 9KW | 12KW |

| Ultrasonic frequency | 28KHZ/40KHZ | ||||

| Tank material | 304/316SUS | ||||

| Tank thickness | 2MM | ||||

| Timer | 1S-99hours adjustable/Normally open | ||||

| Heater | Normal-95℃ adjustable | ||||

| Drain valve | 1 inch | ||||

| Basket & Lid | standard equipped | ||||

| Machine Voltage | AC 220V/380V, 3phases | ||||

| Generator Voltage | AC110V/220V, 1phase | ||||

| Features | 1.with filtration system 2.with casters with brake 3.1 year warranty & tech support for life |

||||

Rolling combine with ultrasonic cleaning, double effect

Automatic rotation

Excellent for Coin, small metal part, bearings, screw, nozzle

Roller ultrasonic cleaning machine, screw cleaning machine

Roller cleaning combine with below typical cleaning process :

Ultrasonic clean Bubble rinsing Hot air drying

![]()

Optional procedure :

Ultrasonic clean Ultrasonic rinsing clean Bubble rinsing Hot air drying

According to the number and requirements of the cleaning Parts, the inner tank dimension and cleaning procedure can be customized.

- Circulating& filtration system: with the circulating filtration system, can quickly separate and filter out the impurities in the cleaning fluid,to keep the cleaning Íiquid clean.

Ultrasonic rinsing clean: adopt the ubiquitous strong cavitation of ultrasonic wave impact effect, accelerate the parts surface with the stripping of dirt, cleaning agents, etc,thus to ensure theparts surface cleanly and efficient cleaning efects.

Machinery industry: removal of rust and grease; cleaning of measuring tools; degreasing and derusting of mechanical parts; cleaning of engines, carburetor and auto parts; dredging and cleaning of filters and filters. Especially in the railway industry, excellent for degreasing and decontaminating the air conditioning of train compartments, derusting, degreasing and rust prevention of various parts of the train head.

Surface treatment industry: degreasing and derusting before electroplating; pre-ion plating cleaning; phosphating; removing carbon deposits; removing scale; removing polishing paste; Instrumentation industry: high cleanliness of precision parts, cleaning before assembly, etc.

Electronics industry: printing circuit boards in addition to rosin, welding spots; high-voltage contacts and other mechanical and electronic parts cleaning. Medical industry: cleaning, disinfection, sterilization, cleaning of laboratory utensils, etc.

Semiconductor industry: High cleanliness cleaning of semiconductor wafers. Watch and Jewelry Industry: Remove sludge, dust, oxide layer, polishing paste, etc. Chemical and biological industries: cleaning and descaling of experimental vessels.

Optical industry: degreasing, de-sweating, cleaning, etc. of optical components. Textile printing and dyeing industry: cleaning textile spindles, spinnerets, etc.

Petrochemical industry: cleaning and unblocking of metal filters, chemical containers, and cleaning of exchangers. Others: photosensitive material manufacturing, paper making,liquid defoaming in certain food areas (removal of dissolved air)